Roll forming is a highly versatile and efficient metal forming process that plays a pivotal role in various industries, from construction to automotive manufacturing. It involves continuously bending and shaping a metal strip or coil into a desired cross-section using a series of rolls or roller dies. This process offers numerous advantages, including cost-effectiveness, repeatability, and the ability to produce complex shapes with high precision and consistency.

Unimacts operates two modern, high-capacity, rolling lines and associated blow-galvanization lines. From these lines, Unimacts provides some of the lowest cost C3/C4 products in the world.

Our facility in Asia operates a high-capacity line for running pre-galvanized forms with the ability to tool up additional lines very quickly and efficiently to improve productivity.

Our newest manufacturing facility in North America enables us to expand production of modern, high-quality forming and tooling to supply and deliver products that meet our customers' stringent specifications and project requirements worldwide.

Our Logistics and Operations Center (LOC), located in Wapato, WA, is the home of our international painting center. This state-of-the-art facility is fully equipped to provide high-quality painting and coating capabilities for a wide range of high-quality, highly specified mechanical industrial parts that we provide to customers worldwide.

Our Wapato LOC’s painting center provides a value added service that augments the capabilities of global supply chains for OEMs. By providing high-quality paint and coating services from the same source as their fabrications, assemblies, castings, and other highly specified mechanical industrial parts.

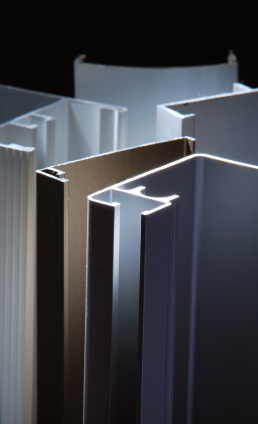

Aluminum extrusions can create complex shapes from aluminum. An aluminum extrusion uses a continuous solid bar of aluminum that is cut into sections as needed. These sections are then shaped through a series of precise and controlled machining processes.

Aluminum extrusion profiles can be easily customized to your needs and there are many benefits to building objects with aluminum. Unimacts also specializes in rapid manufacturing of prototype aluminum extrusions.

Extruded aluminum is often used in manufacturing auto parts for engine blocks, transmission housings, and vehicle and truck bodies. It is also a good material for housing copper or fiber optic cables or wires.

In the building and construction industry, extruded aluminum components can help resist distortion caused by weather and building movement. They retain their strength and flexibility even under loads and spring back from the shock of impact.

Unimacts offers fast, reliable, and cost-effective injection molding services. Injection molding is a production process that uses pressure to force molten plastic into molds to create useful parts. Injection-molded components are mass-produced in various plastic materials. Depending on the tool type, the number of parts can vary from a few thousand to millions. Injection-molded parts are used in a wide variety of industries, including automotive, consumer goods, and medical devices.

Injection molding can produce parts in a wide range of sizes and complexity. Small features, intricate geometries, and thin walls can be captured with ease using the injection molding process. Injection-molded components can be post-processed via various surface finishing options such as painting and texturing.