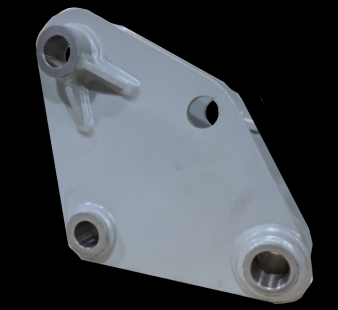

Working with Unimacts, your team adds a level of engineering expertise and experience that has delivered thousands of containers of assemblies, mechanical parts, fabrications, castings, and slewing rings worldwide. Unimacts specializes in building custom supply chain solutions for original equipment manufacturers (OEMs) of construction and industrial equipment. At Unimacts, we offer deep technical expertise in manufacturing highly specified, highly engineered components. As your supply chain solutions provider, we work with our customers to augment your supply chain team and capabilities to deliver low-risk solutions with world-class cost and quality ultimately.

Unimacts is ISO9001/2015 certified and our UOS (Unimacts Operating System) is based on Lean Six Sigma. Our materials, welding and coating processes are typically based on ASTM, AWS, or EN specifications. These industry certifications help ensure that your machinery projects are built to and uphold the highest quality and performance standards.

At Unimacts, we bring expertise and innovation to precision manufacturing across the renewable energy sector.

Unimacts is ISO 9001/2015 certified and our UOS (Unimacts Operating System) is based on Lean Six Sigma. Our materials, welding and coating processes are typically based on ASTM, AWS, or EN specifications. These industry certifications help ensure that your solar projects are built to and uphold the highest quality and performance standards.