Taking Your Supply Chain to New Heights

Working with Unimacts, your team adds a level of engineering expertise and experience that has delivered thousands of containers of assemblies, mechanical parts, fabrications, castings, and slewing rings worldwide. Unimacts specializes in building custom supply chain solutions for original equipment manufacturers (OEMs) of construction and industrial equipment. At Unimacts, we offer deep technical expertise in manufacturing highly specified, highly engineered components. As your supply chain solutions provider, we work with our customers to augment your supply chain team and capabilities to deliver low-risk solutions with world-class cost and quality ultimately.

Unimacts is a global contract manufacturer specializing in building custom supply chain solutions for Western Original Equipment Manufacturers (OEMs). Typically, we operate as an extension of our customer’s supply chain, engineering, and supplier quality teams. Whereas these functions may not be a core competency for our customers, At Unimacts, managing a lean and low-cost global supply chain is what we do. Our focus is on developing and producing highly specified, complex engineered metal components, allowing our customers to capitalize on the benefits of a low-cost global supply chain while also mitigating the quality and delivery risks typically associated with low-cost country sourcing.

From our factories overseas, Unimacts engineers work hand-hand with our supply partners to manage production and quality. Our Logistics team ensures effective routing and customs clearance for all shipped products and leverages global freight volumes to negotiate low-cost rates. Locally, our warehousing and distribution teams, established near customer sites around the US and Europe, provide one final layer of quality control and arrange just in time delivery. Ultimately, the Unimacts solution not only delivers a low-risk solution with world-class cost and quality, but it also enables our customers to shift their energy, resources, and focus to their end-product and end-customer needs.

The construction machinery and material handling markets reflect one of our top three markets globally for more than a decade because the demands of the industry are perfectly aligned with Unimacts' operating priorities:

- Safety-critical fabrication

- World-class quality

- Greater reliability

- Enhanced productivity

- Reduced manufacturing costs

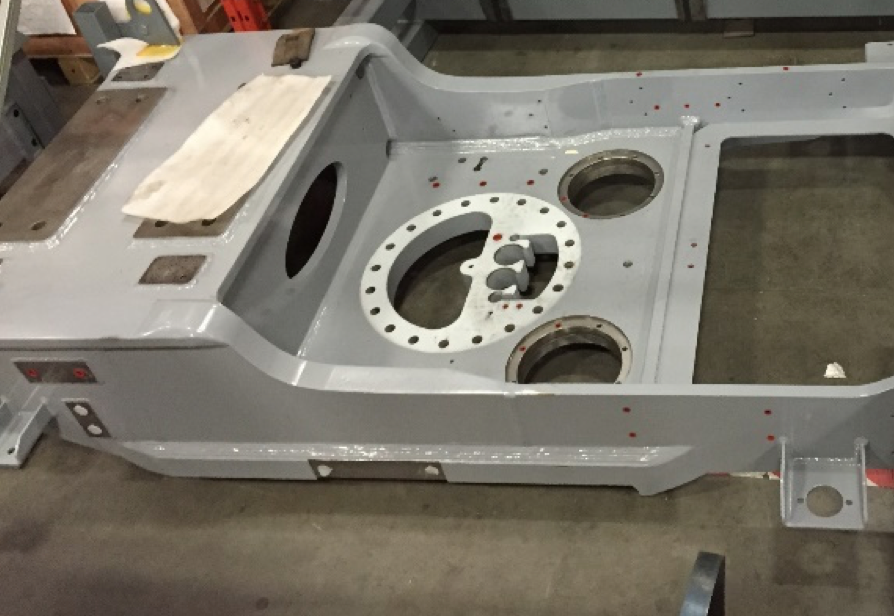

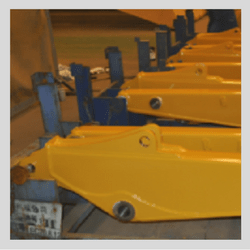

Fabrications

Our fabrications are constructed to AWS standards from verified materials in certified mills and modern shops.

Our Processes Are:

- Various Weld Capabilities including MIG, GMAW/TIG, FCAW, Resistance/Spot

- Precision (Pre and Post) Machined Weldments

- Robotic and Manual Welding

- Pre and Post Weld Heat Treatment

- Robust Tooling Design and Development

- Applications ranging from safety-critical and heavy industrial to light gauge on carbon and stainless steels

Commodities/Common Applications:

- Scissor Links

- Booms/Arms

- Swing and Drive Chassis

- Frames

- Axles

- Tanks and Pressure Vessels

- Fabricated Counterweights

- Aftermarket Attachments

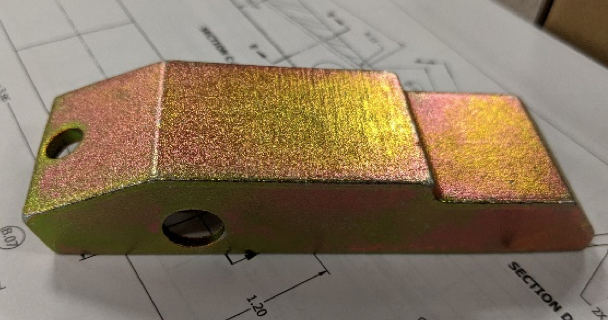

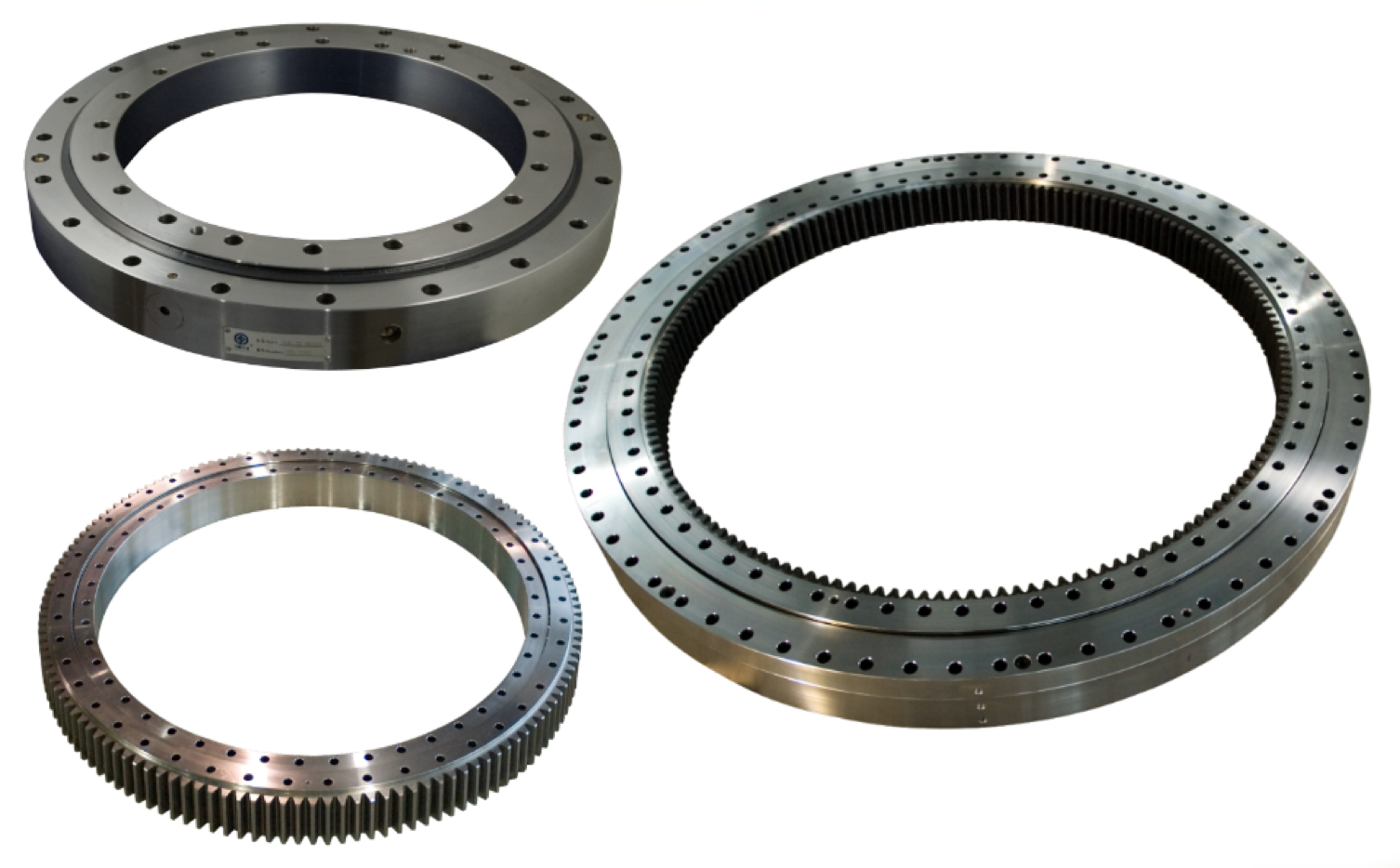

Forgings

Processes

- High Strength Forgings and Rings

- Precision Machining

- Heat Treatment and Strengthening

Commodities/Common Applications

- Slewing Rings

- Gears

- Shafts

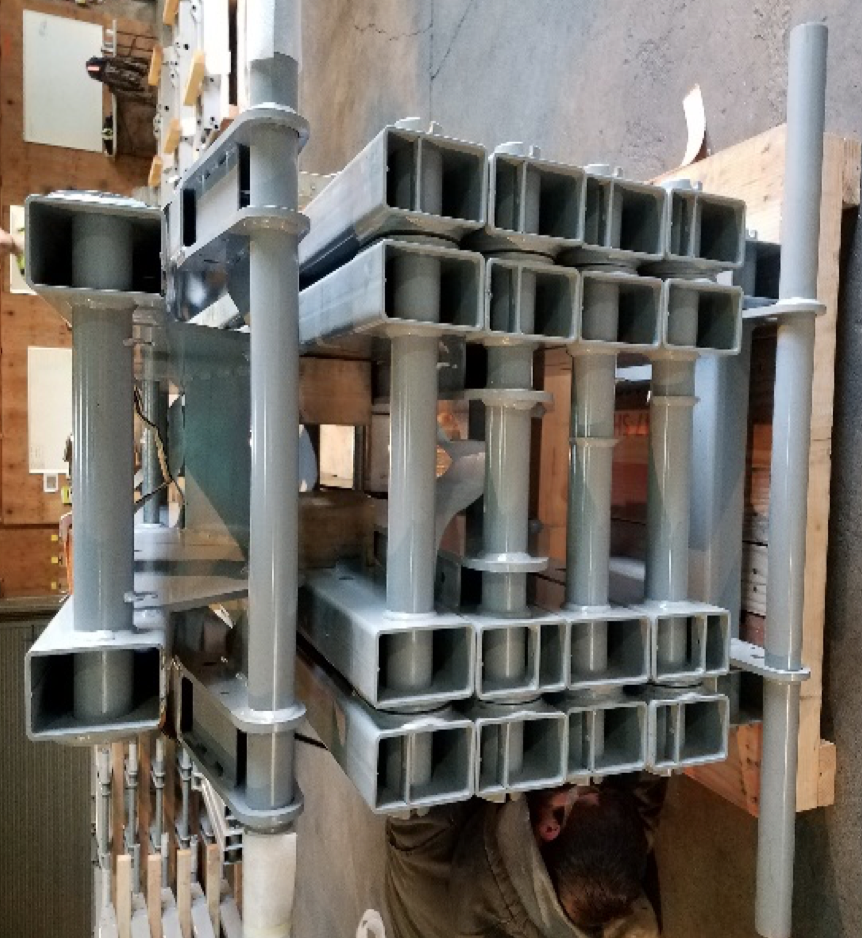

Assemblies

Unimacts supplies fully inspected, line-ready parts complete with:

- Link stacks

- Knockdown kits

Castings

Our castings are fully certified, and many are engineered to x-ray quality standards.

Our Processes Are:

- Green Sand Casting – Iron, Ductile Iron, Bronze, Alloy Steel, Stainless Steel

- Vacuum Sand Casting – Iron and Ductile Iron

- Investment Casting - Steel

- Die Casting (Low Pressure and High Pressure) – Steel and Aluminum

Commodities/Common Applications:

- Counterweights

- Gearboxes

- Spindles and Yokes

- Attachments

Associated Equipment/Instruments

- Pins and bushings

- Specialty fasteners

- Mechanical equipment and instruments

Industrial Certifications

Unimacts is ISO9001/2015 certified and our UOS (Unimacts Operating System) is based on Lean Six Sigma. Our materials, welding and coating processes are typically based on ASTM, AWS, or EN specifications. These industry certifications help ensure that your machinery projects are built to and uphold the highest quality and performance standards.

These certifications are designed to help provide the following benefits:

- Consistently meet regulatory and customer requirements

- Improve product quality

- Eliminate problems

- Remove waste and inefficiency

- Improve working conditions to respond better to your needs