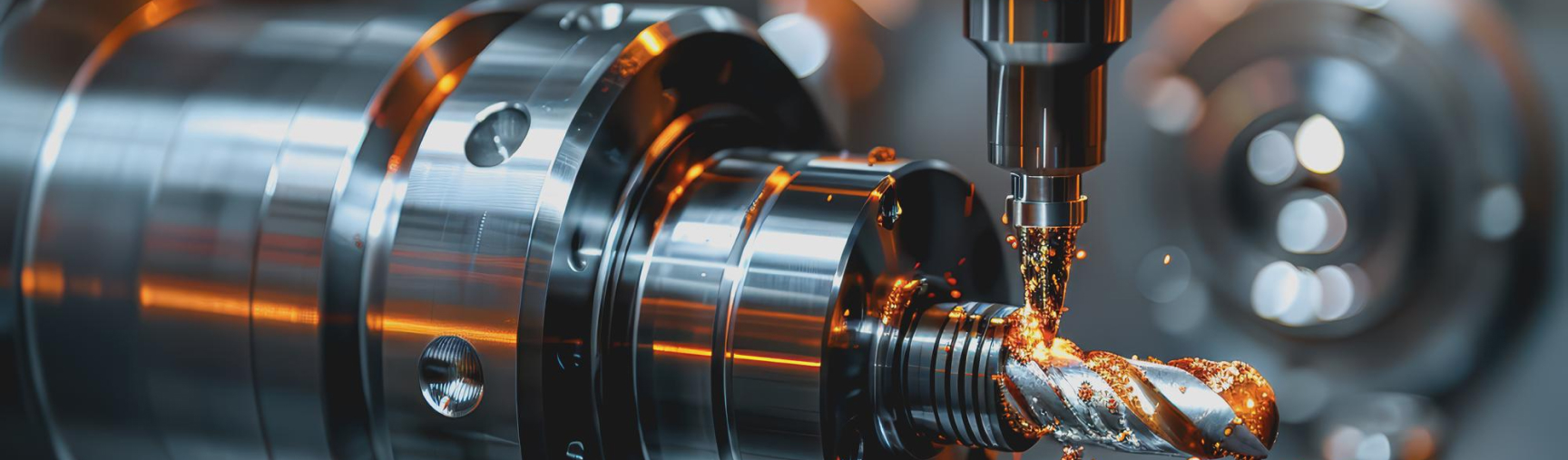

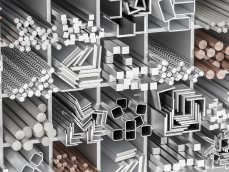

Unimacts machining factory is fully equipped with state-of-the-art equipment and in-house engineering services. We employ experienced, professional staff to ensure consistent compliance with your engineering specifications and provide high-quality, tight-tolerance components machined from bar stock.

3 Axis, 4 Axis & 5 Axis, Double Column Vertical Machining Center, Multi Spindle Vertical Machining Center, Horizontal Machining Center

Turn Mill Centres, Mill-Turn Centres, Turning Centres, Profile Grinding

Cyl, Surface & Profile Grinding, Honing, and Lapping,

EDM, Thread Rolling, Gear Hobbing, Shaping, Broaching, Spline Cutting, Gun Drilling, etc.

Unimacts provides inspection services including Scanning, CMM, VMS, Gauging, Shadowgraph, NDT, Contour Profiling, and Scanning.

These include Master Cam, Hyper Mill, UG NX, and Solid Works.

Once production components are CNC machined, they are subjected to one or more finishing processes to remove the any deformities and achieve tolerances. Some of the secondary operations and finishing processes offered:

Phosphating, blasting, Anodising, Zn & Zn-Ni Plating, Passivation, Alodine, Abrasive blasting, Cd, etc.

Nitriding, Stress relieving by using hardening, Nitriding, and Carburising.

Unimacts is ISO 9001/2015 certified and our UOS (Unimacts Operating System) is based on Lean Six Sigma. Our materials, welding and coating processes are typically based on ASTM, AWS, or EN specifications. These industry certifications help ensure that your solar projects are built to and uphold the highest quality and performance standards.